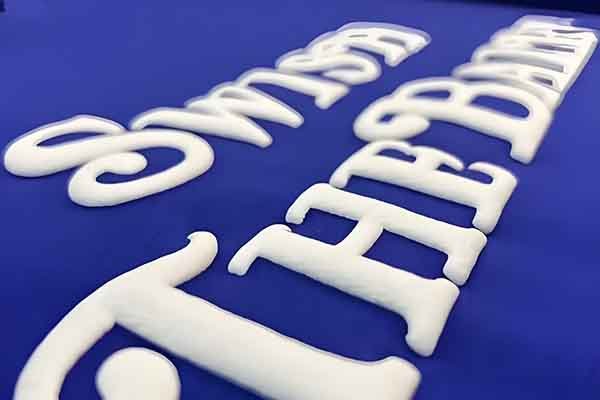

What Is Puff Print? A Complete Guide to 3D Puff Printing and Puff Print Transfers?

Puff printing is a special type of screen printing. It makes a three-dimensional design on fabric. It feels raised and looks puffed up. Puff printing

Turn ordinary eco fashinable bags into signature pieces with custom printing logos. From screen printing , embroidery to flocking and heat transfers, we provide tailored solutions to match your materials, order size, and budget — giving your products a unique, high-quality finish.

Screen printing is one of the most common and cost-effective printing methods. It works well on almost all types of materials, making it highly versatile and widely used across industries.

However, it is not ideal for complex or multi-color designs. The more colors involved, the higher the printing cost, since each color requires a separate screen. This method is best suited for simple, bold logos, text, or single-color artwork where durability and clarity are important.

Thermotransferdruck allows for unlimited colors, producing bright, vivid, and detailed results. It is a great choice for complex patterns, full-color logos, or photo-like images where precision and vibrancy matter.

However, this method has certain limitations. It is restricted by the type of material and the printable area. The process is slower and more expensive compared to other techniques, and the printed surface may have a slight adhesive or plastic-like feel.

Digital printing works on a wide range of materials and supports unlimited colors, making it highly versatile. Unlike traditional methods, it is not restricted by printing area and can handle both small and large designs with ease.

It is particularly suitable for multi-color or gradient artwork, offering high detail and precision. However, the process is relatively slow and more expensive compared to simpler techniques, making it better suited for smaller batches or custom designs rather than mass production.

Sublimation printing is a digital printing technique mainly used on polyester fabrics or surfaces with a special polymer coating. During the process, heat and pressure turn solid dye into gas, allowing it to penetrate the fibers of the material. This results in a permanent, full-color design that will not crack, peel, or fade easily.

This method is excellent for producing vibrant, photo-quality images with fine details and smooth gradients. However, it is less suitable for natural fabrics like cotton and is generally limited to light-colored surfaces, as the sublimation process cannot print white ink.

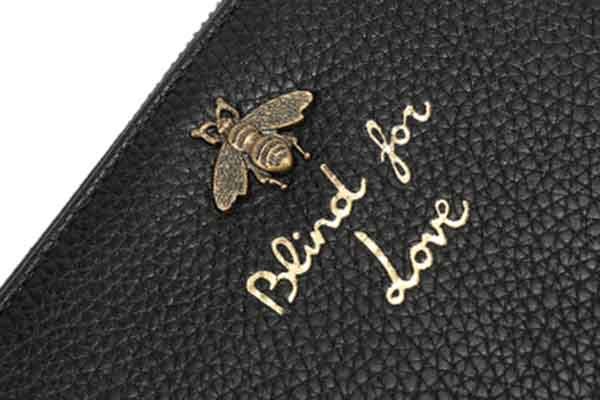

Gold stamping is a decorative printing technique often used on paper, leather, and fabric surfaces. It applies metallic foil—commonly gold, but also available in silver or other colors—using heat and pressure to create a shiny, reflective finish.

This method adds a premium, elegant look to logos, patterns, or text. It is especially popular for branding, packaging, and luxury products. However, it works best on flat surfaces and is less suitable for large, highly detailed, or gradient designs, as the foil effect emphasizes bold shapes and clean lines.

Puff printing is a special technique commonly used on cotton and canvas fabrics. It also works well on smooth surfaces, though the surface should not be too glossy. During the heating process, the ink expands and creates a raised, textured finish that gives the design a 3D appearance.

This method is excellent for adding a tactile effect and visual depth to logos or text. However, it is less suitable for highly detailed or multi-color designs, as the puff effect may reduce fine-line sharpness.

Flocking works best on a limited range of materials and creates a soft, velvety texture that feels premium and visually elevates the product. The flocked surface is durable and not prone to shedding, giving a high-end, sophisticated look.

However, this method is relatively expensive, and larger print areas will increase the cost. It is best suited for small logos or accent details that require a luxurious touch.

Embroidery works well on almost all types of materials and gives a handcrafted, premium look with a strong three-dimensional effect. It adds a sense of durability and sophistication, making it a popular choice for logos, monograms, and decorative elements.

However, embroidery is generally more expensive than other printing methods. The more complex the design, in terms of colors and patterns, the higher the cost. It is best suited for simple yet impactful designs where a textured, high-end finish is desired.

UV printing is a digital printing method that uses ultraviolet light to cure specially formulated ink directly onto the surface of the material. It works on a wide range of substrates, including plastic, metal, glass, wood, and coated fabrics. The cured ink creates a sharp, durable print that is resistant to scratches and fading.

This method is excellent for multi-color designs, gradients, and even photo-quality images. It also allows for printing on irregular or rigid surfaces without the need for special coatings. However, it is less suitable for flexible fabrics that require frequent washing, as the cured ink layer may crack when bent or stretched repeatedly.

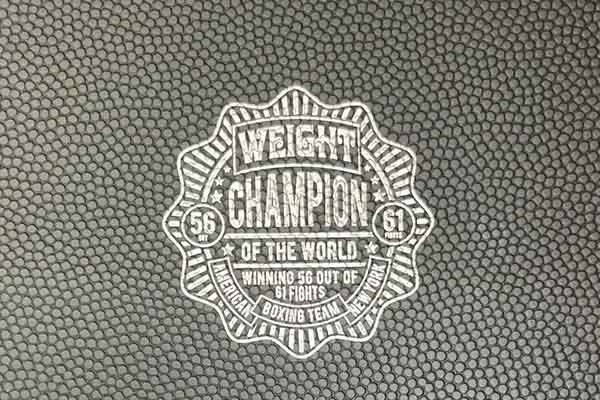

Laser engraving is a precision technique that uses a focused laser beam to etch designs directly onto the surface of a material. It works well on metal, wood, glass, leather, and certain plastics, creating permanent marks with fine detail. The engraved areas have a subtle, textured look that will not fade or peel over time.

This method is excellent for logos, text, and intricate patterns that require durability and precision. It is especially popular for branding, personalized products, and high-end packaging. However, it does not add color to the design, and it is less suitable for large, full-color graphics where vibrant visual impact is required.

Appliqué embroidery is a decorative technique that combines fabric pieces with stitching to create layered designs. A base fabric is cut into shapes and sewn onto the main material, often with embroidery details added around the edges to secure and highlight the design. It works well on cotton, canvas, felt, and other sturdy textiles.

This method adds texture, color contrast, and a handmade aesthetic, making it excellent for logos, letters, or bold patterns. It is especially popular in fashion, uniforms, and custom accessories. However, it is less suitable for highly detailed or very small designs, as the layered fabrics may affect precision and increase production time.

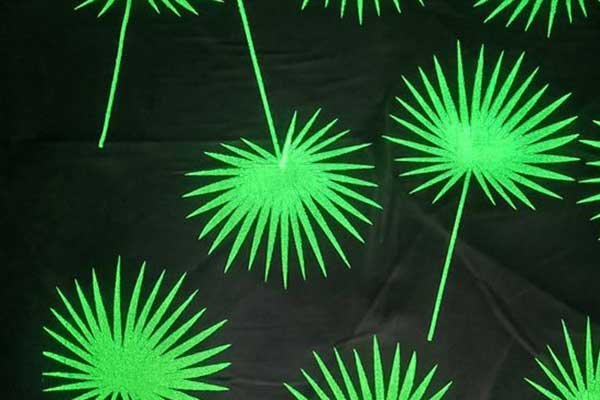

Glow in the dark printing is a special technique that uses phosphorescent inks to create designs that emit light in darkness after being exposed to a light source. It works well on cotton, canvas, polyester, and some coated surfaces. During the printing process, the ink is applied like traditional screen or digital printing and then cured to ensure durability.

This method is excellent for adding a fun, eye-catching effect to logos, text, or patterns, making products stand out in low-light environments. However, it is less suitable for highly detailed or multi-color designs, as the glow effect is most effective with bold shapes and simple graphics. The brightness and duration of the glow also depend on the type of ink and exposure to light.

| Printing Method | Suitable Materials | Best Quantity | Wesentliche Merkmale |

|---|---|---|---|

| Screen Printing | Cotton, Canvas, Jute, Non-woven | 200+ pcs | Bold colors, best for 1-2 colors |

| Pad Printing | Cotton, Canvas, small areas | 200+ pcs | Good for small logos or irregular surfaces |

| Heat Transfer | Cotton, Canvas, Polyester | 500+ pcs | Full-color, gradients, detailed graphics |

| DTG Printing | Cotton, Canvas | 100+ pcs | Photo-quality, suitable for personalized designs |

| DTF Transfer | Cotton, Canvas, Non-woven, Polyester | 100+ pcs | Sharp details, flexible for small orders |

| Sublimation | Polyester, RPET Bags | 500+ pcs | Vivid colors, non-fading, needs white/light base |

| UV Printing | Polyester, Leather trim, Hard surfaces | 100+ pcs | Gloss or emboss effects, high-end look |

| Flocking Print | Cotton, Canvas, Jute | 500+ pcs | Velvet texture, soft touch |

| Puff Printing | Cotton, Canvas | 500+ pcs | Raised 3D effect, thick ink feel |

| Glow in the Dark | Cotton, Canvas, Non-woven | 500+ pcs | Glows at night, normal in daylight |

| Neon Printing | Cotton, Canvas, Jute | 500+ pcs | Bright fluorescent colors, eye-catching |

| Glitter Print | Cotton, Canvas, Jute | 500+ pcs | Sparkle effect, decorative style |

| Water-based Printing | Light Cotton, Canvas | 1000+ pcs | Eco-friendly ink, breathable finish |

| Discharge Printing | Dark Cotton, Canvas | 1000+ pcs | Removes base color, soft natural feel |

| Stickerei | Cotton, Canvas, Jute | 300+ pcs | Premium look, textured threads |

| Woven Label / Patch | Cotton, Canvas, Jute | 500+ pcs | Brand label sewn on, high-quality touch |

| Silicone Printing | Cotton, Canvas, Polyester | 500+ pcs | Soft rubbery feel, durable |

| Rubber Patch | Cotton, Canvas, Jute, Polyester | 500+ pcs | 3D rubber badge, strong branding |

| Laser Engraving | Leather trim, Special materials | 100+ pcs | Unique carved effect, premium style |

Get more details about our printing methods or send us your design ideas — our team will guide you through the process.

Common techniques include screen printing, heat transfer, DTG (direct-to-garment), DTF (direct-to-film), sublimation, embroidery, foil stamping, flocking, puff print, glow-in-the-dark, neon, and glitter printing.

Yes. Complex designs, gradients, or photo effects are best done with heat transfer, DTG, or DTF. Screen printing is better for simple logos and graphics.

Large-scale screen printing and sublimation offer stable color consistency. Small batches with heat transfer or DTG may have slight color variations, which is normal.

Generally no. However, thick ink layers or glitter prints may wear slightly with long-term use. Embroidery and sublimation are the most durable.

Yes, but it depends on the method:

Screen printing, embroidery, and sublimation are highly washable

Heat transfer, glitter, and neon prints should avoid long soaking or high-temperature washing

Yes. For screen printing, the more colors, the higher the cost. DTG, heat transfer, and DTF allow full-color printing with relatively stable costs.

Yes, options include 3D texture (puff/flock), metallic shine (foil), glow-in-the-dark, neon, and glitter.

Yes, for example embroidery with screen printing, or foil with heat transfer, to achieve both texture and color.

Vector files (AI, PDF, CDR) are preferred. High-resolution images are also acceptable for clear output.

Cotton/Canvas: screen printing, DTG, embroidery

Polyester/Non-woven: heat transfer, DTF

RPET/Nylon: sublimation, foil

Normally 1–3 years under regular use. Screen printing, embroidery, and sublimation last the longest.

Mainly printing method, number of colors, design complexity, print size, and order quantity.

Yes, such as the front, back, sides, bottom, or handles. Some methods may have placement limitations.

Some methods require it: screen printing needs drying, puff/flock needs heat curing, and foil needs pressing.

Puff printing is a special type of screen printing. It makes a three-dimensional design on fabric. It feels raised and looks puffed up. Puff printing

If you’re a business, your main aim will be to stand out. Logos help represent your company, which is why they should be easily recognizable.

The market for canvas tote bags is estimated to grow at a rate of 4.60% in the next seven years. More and more businesses are adopting

Als ein führendes Hersteller kundenspezifischer Ökotaschen in China, ist Avecobaggie spezialisiert auf Nachhaltige OEM/ODM-Verpackungslösungen für globale Marken. Wir produzieren zertifizierte wiederverwendbare Taschen (Bio-Baumwolle, RPET, kompostierbare Materialien) mit Servieren Einzelhandel, Gastgewerbe und Werbebranche.

Unser End-to-End-Dienst deckt Designunterstützung, niedriges MOQ und exportfertige Logistik.

Sandra

Antwortet in der Regel innerhalb von Minuten

Möchten Sie Ihre eigene Tasche entwerfen? Lassen Sie uns jetzt chatten...

Kontakt

🟢 Online | Datenschutz

WhatsApp us

Gratis Avecobaggie erhalten E-Katalog