Procurement managers often face a dilemma: a custom bag that fits the budget might fail to impress the target audience. If the product does not match the actual usage scenario, your marketing investment yields zero return.

Selecting the right custom waist bag requires aligning technical specifications with business objectives. Whether for trade show giveaways, retail product lines, or corporate gifts, understanding the specific use case ensures you balance unit cost, lead time, and brand impact effectively.

Many buyers focus solely on the lowest price per unit. However, a strategic approach looks at the total value and the application context.

WHY Do Different Use Scenarios Require Different Custom Waist Bag Designs?

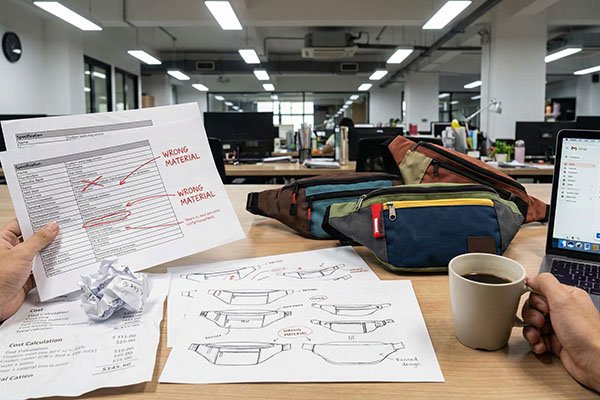

A standard "one-size-fits-all" specification sheet rarely satisfies diverse business needs. Why does a generic approach often lead to wasted inventory and poor brand perception?

Different business scenarios demand specific trade-offs between durability, functionality, and cost. A high-volume promotional event prioritizes low unit cost, while a retail product requires premium materials and complex structures to justify a higher sales price.

In the B2B context, the "Use Scenario" dictates the manufacturing standard. We often see brands try to use the same specification for a massive giveaway and a VIP client gift. This is a strategic error. A giveaway item focuses on cost-efficiency and logo visibility. It needs to be lightweight for cheap logistics. A retail or VIP item focuses on perceived value and longevity.

If you choose a complex structure for a simple promotional event, you increase your manufacturing time and costs unnecessarily. The end-user at a crowded trade show does not need five zipper compartments; they need a simple pouch for brochures. Conversely, if you sell a "running belt" that uses cheap, non-elastic materials, your product reviews will be negative. The scenario defines the material cost, the sewing complexity, and the minimum order quantity (MOQ).

| Business Scenario | Priority Factors | Typical Material | Cost Structure |

|---|---|---|---|

| Trade Show Promo | Low Price, Fast Delivery | 190T/210D Polyester, Non-woven | Low Material, Low Labor |

| Corporate Gift | Brand Image, Quality Feel | Canvas, 600D Polyester, rPET | Medium Material, Medium Labor |

| Retail / Outdoor | Function, Durability, Features | Ripstop Nylon, Waterproof Coating | High Material, High Labor |

You must define the purpose before you open the material swatch book. This decision drives every subsequent step in the supply chain.

WHAT Factors Should Brands Consider When Choosing a Custom Waist Bag?

A technical pack might look perfect on paper, but does it translate to a viable product? How do specifications like capacity and material affect your brand’s reputation?

Brands must evaluate capacity relative to modern devices, material suitability for the environment, and appropriate branding techniques. Misjudging these factors leads to products that are either too expensive to produce or too cheap to be useful.

From a procurement perspective, "Capacity" is not just about liters; it is about utility. We advise clients to measure the standard equipment their target demographic carries. For most modern scenarios, the bag must accommodate a large smartphone (approx. 6.7 inches) and a passport. If the pattern is too small by even 1 cm, the product becomes useless inventory.

Material selection is a balance of cost versus performance. Polyester is the industry standard for cost-effective promotions. However, for brands focusing on ESG (Environmental, Social, and Governance) goals, rPET (recycled polyester) is the superior choice. It costs slightly more but provides a marketing story that appeals to modern consumers. Canvas offers a natural, premium look suitable for lifestyle brands but lacks water resistance.

Branding methods also impact the budget and timeline. Silk screen printing is standard for high-volume orders. However, it can crack over time on flexible fabrics. For higher-end corporate gifts, we recommend embroidery or rubber patches. These methods cost more and require longer production times, but they significantly elevate the perceived value of the item. You must align the branding durability with the expected lifespan of the bag.

HOW Should Brands Select Custom Waist Bags for Events and Promotions?

Deadlines are fixed and budgets are tight. How do you select a specification that maximizes brand visibility without overspending?

For mass events, choose simple structures with high-contrast printing areas. For specialized uses like sports or festivals, prioritize functional materials and trend-conscious designs to ensure the item is kept and used long-term.

We need to segment your procurement strategy based on the specific type of event.

Trade Shows and Large Conferences:

The goal here is "Cost Per Impression." You need a bag that acts as a walking billboard. Choose a flat design (2D structure) because it is cheaper to sew and cheaper to ship in bulk. Use bright colors and a large print area. Do not over-engineer the pockets. Speed of production is key here.

Outdoor and Sporting Events:

The goal changes to "Functionality." If you sponsor a marathon, the bag must be a performance product. You must specify lightweight, water-resistant fabrics and secure buckles. If the bag bounces or breaks during the run, it damages your brand equity. In this scenario, function outweighs the size of the logo.

Employee Gifting and Internal Use:

The goal is "Employee Satisfaction." Do not treat your team like trade show attendees. Internal gifts require a retail-level quality approach. Use neutral colors (Grey, Black, Navy) that fit into daily life. Focus on tactile quality—zippers that slide smoothly and fabrics that feel thick. A high-quality internal gift boosts morale; a cheap one feels insulting.

Festivals and Pop-up Retail:

The goal is "Social Sharing." The design needs to be visually striking. This is where you experiment with metallic fabrics, Tyvek, or clear PVC. The bag serves as a fashion accessory. The MOQ might be lower, but the unit price will be higher to cover unique materials.

HOW Do Material and Structure Affect Custom Waist Bag Performance in Real Use?

Why do some production batches face high complaint rates? How do invisible details like coating and hardware impact the long-term reliability of your product?

Fabric weight and hardware quality are the primary drivers of durability. Complex structures with multiple seams increase the risk of defects and production costs. A rigorous pre-production sample review is the only way to mitigate these quality risks.

In manufacturing, small details have huge cost and quality implications. Let’s talk about fabric weight. 190T or 210D polyester is very thin. It is cheap, but it has no structure; it hangs loosely. For a professional B2B product, we recommend at least 600D Oxford cloth. It holds its shape and feels like a "real" product, which increases the perceived value of your brand.

Hardware is often where suppliers cut corners to lower the price. A generic plastic buckle might look the same as a branded one, but it may snap under pressure. For any bag intended for travel or sports, you must specify reinforced stitching at the strap attachment points. If these points fail, the bag falls off.

Structure complexity directly correlates with labor costs. Every zipper, every lining pocket, and every piping edge adds minutes to the sewing line. It also increases the defect rate. If you are working with a tight budget, it is better to choose a simple design with high-quality fabric than a complex design with low-quality fabric. A complex bag made cheaply will always fail.

Furthermore, sample testing is non-negotiable. You cannot judge a bag’s structure from a PDF file. You must fill the sample with weights and wear it to test the fit and the zipper strength.

WHAT Common Mistakes Do B2B Buyers Make When Customizing Waist Bags?

Why do some projects end up with stock that sits in a warehouse? What are the frequent pitfalls in the planning and procurement process?

Buyers often overlook the end-user demographics, focus excessively on unit price while ignoring utility, or fail to account for the impact of design changes on MOQ. These errors disrupt the supply chain and reduce the ROI of the project.

The most common error we see is a disconnect between the buyer and the user. A procurement manager might choose a small, sleek bag to save on shipping volume. But if the end-users are construction workers or large demographics, the strap might be too short, or the bag too dainty. You must design for the user’s body type and daily habits, not just for the shipping container.

Another critical mistake is "Feature Creep." A project starts with a target price. Then, the marketing team asks for a waterproof zipper. Then, they want a custom molded puller. Then, they want a specific Pantone-dyed lining. Suddenly, the cost has doubled, and the factory requires a higher MOQ because the materials are custom. You must lock the specifications early.

Finally, many buyers fail to test the "loaded" state of the bag. A bag might look perfect when stuffed with paper in the factory. But when you put heavy items like a power bank inside, the structure might collapse or tilt forward awkwardly. Always test the pre-production sample with real-world contents. This simple step saves thousands of dollars in potential claims.

Заключение

Effective procurement starts with a clear definition of the usage scenario. By aligning specifications with the business goal—whether it is promotion, retail, or gifting—you ensure the final product delivers value and protects your brand reputation.

Frequently Asked Questions

Q: What file formats do you need to produce a clear logo print on waist bags?

A: For the best results in silk screen or heat transfer printing, we require vector files. Please provide your artwork in AI (Adobe Illustrator), PDF, or EPS formats. If you only have a JPG or PNG, the resolution must be at least 300 DPI, but vector is always preferred to ensure crisp edges and accurate color separation.

Q: Can we dye the fabric to match our specific Brand Pantone color?

A: Yes, but this affects the Minimum Order Quantity (MOQ). If you use stock fabric colors (black, grey, navy, etc.), the MOQ is flexible. If you require a custom Pantone dye for the main body fabric, the fabric mill usually requires a minimum of 1,000 yards, which translates to a significantly higher bag order (often 3,000+ pieces depending on size).

Q: How does the "volume weight" of waist bags affect international shipping costs?

A: Waist bags, especially those with foam padding or 3D structures, are bulky. Shipping companies charge based on volume weight, not just actual weight. To reduce costs, we can discuss packaging solutions like opp bag compression or nesting the bags to minimize air space in the carton, which can save 20-30% on freight.

Q: Do you offer sustainable certifications for the rPET material mentioned?

A: Yes. For clients requiring rPET (recycled polyester), we can provide a GRS (Global Recycled Standard) transaction certificate. This document tracks the recycled content from the source to the final product, ensuring your sustainability claims are legally and ethically verified.

Q: What is the typical lead time for a custom waist bag order from China?

A: After sample approval, mass production typically takes 25 to 35 days. However, you should also account for 5–7 days for sample creation and 30–40 days for ocean freight (if shipping to the US or EU). We recommend starting your inquiry at least 3 months before your event date.

Q: Can you add custom hangtags and private wash labels for retail orders?

A: Absolutely. For retail projects (Private Label), we strongly recommend adding a custom hangtag with your barcode and a sewn-in wash label with your brand name and care instructions. This is often a legal requirement for customs entry in the US and EU and adds to the retail readiness of the product.

Q: Is there a cost for the pre-production sample?

A: Yes, we charge a sampling fee to cover the cost of pattern making, material sourcing, and machine setup. However, this fee is typically refundable if the subsequent bulk order meets our MOQ requirement. This ensures that both parties are serious about the project.

Q: How do we ensure the waist bags comply with California Prop 65 regulations?

A: If you are selling or distributing in California, the materials (fabric, zippers, and coatings) must be free of restricted heavy metals and phthalates. Please inform us at the inquiry stage so we can source Prop 65-compliant raw materials and arrange for third-party lab testing (like SGS or Intertek) if needed.

Q: Can we make changes to the design after the deposit is paid?

A: It is very difficult and costly. Once the deposit is paid, we immediately purchase the fabric and cut the materials. Changing the size or structure at this stage would mean scrapping the cut fabric, and you would be responsible for those material costs. This is why the sampling stage is the only time to finalize design details.