Single-use plastic makes travel kits feel cheap and wasteful. Customers demand sustainability, but traditional packaging ends up in the trash instantly. Brands lose a chance to make a lasting impression.

Reusable bags transform disposable packaging into lasting brand assets. Cotton canvas zipper pouches and drawstring bags protect travel-size products better while offering customers a useful item kept for years.

Many brands hesitate to switch because of cost concerns. However, the market is shifting rapidly. Customers now expect eco-friendly solutions. If this trend is ignored, competitors offering better value will take the lead.

Why are cosmetic and personal care brands switching to reusable packaging bags?

Single-use plastic packaging limits the value of a product. Customers see it as trash. It is thrown away as soon as the kit is opened. This wastes money.

Brands switch to reusable bags to increase brand touchpoints. Unlike throw-away boxes, a quality fabric bag adds value to gift sets and promotional bundles, turning packaging into a standalone product. This improves customer retention and reduces waste.

Traditional packaging for travel-size kits often presents a significant problem. Paper boxes crush easily inside luggage during transport. Plastic bags often tear and feel cheap to the touch. Reusable bags solve these issues effectively. These items function as both packaging and a standalone product. When a customer purchases a travel kit, the products are consumed, but the packaging remains. The bag stays in use. It serves for gym trips or future travel. This continuous usage increases brand visibility significantly. This represents true sustainability. It goes beyond a simple slogan. The focus shifts to reuse rates.

This trend is clearly visible in gift sets and promotional bundles. A cotton bag adds a premium feel to a set. It justifies a higher price point for the brand. Companies aim to connect with users. Disposable packaging breaks that connection immediately. Reusable bags build it. The bag becomes a constant reminder of value. A one-time purchase turns into a long-term relationship. This drives the shift away from plastic. The goal is to make the packaging as desirable as the product itself.

What types of reusable bags work best for travel-size products?

Choosing the wrong bag shape ruins the unboxing experience. Products slide around or spill. Customers get frustrated when the bag does not function well. This hurts brand reputation.

Zipper bags, drawstring bags, and small tote bags are the top choices. Zipper pouches secure liquids best. Drawstring bags suit dry goods. Small totes elevate high-value retail sets.

Choosing the right shape for specific items is critical for success. Zipper bags remain popular for distinct reasons. These pouches work perfectly for liquids, shampoos, and skincare bottles. The zipper secures the contents inside. It prevents leaks within a suitcase. This feature is vital for travel products. Cotton canvas is often recommended for these bags. The material is sturdy and washes easily if spills occur.

Drawstring bags serve a different purpose. These work well for dry items. Makeup tools, cotton pads, or solid soaps fit perfectly. The flexible nature allows them to fit into tight luggage spaces. Small tote bags act differently. These resemble mini shoppers. They suit high-value gift sets or retail displays. The item acts like a gift bag kept by the customer. Cost plays a role here too. Drawstring bags generally cost less to manufacture. Zipper bags require a higher investment but offer better security. Balancing cost with product value is necessary.

| Стиль сумки | Best Application | Primary Benefit |

|---|---|---|

| Canvas Zip Pouch | Liquid bottles, creams | Secure closure, prevents leaks |

| Сумка на завязках | Dry tools, cotton pads | Flexible, lightweight, cost-effective |

| Small Tote Bag | Gift sets, retail display | Premium look, high reuse value |

How do brands choose the right bag size for cosmetic and toiletry sets?

A bag that just barely fits the product looks unprofessional. Tight fits rip seams. Loose fits look sloppy. This destroys the premium feel and frustrates users.

Do not just measure the product volume. Consider the combination of items and future use. A slightly larger bag improves the user experience and encourages secondary use.

A common mistake involves sizing decisions. Brands often measure bottles exactly and match the bag size perfectly. This approach is incorrect. A bag needs "breathing room." Three main factors require attention. First is the combination size. A kit with three bottles must be measured as a group, not individually. Second is the usage scenario. Carry-on suitcases require compact designs. A size around 8 x 5 x 2 inches works well for most travel needs.

Third is future reuse. A bag that is too small becomes useless later. It fits the product initially, but the customer cannot use it for other purposes. A slightly larger bag fits a phone or keys later. If the bag is too small, the user struggles to close it. This creates a bad experience. If it is too big, the products rattle inside. This increases shipping costs and wastes material. Finding the perfect balance is key. It fits the product now. It fits the customer’s life later.

Why is product dimension enough to design custom packaging bags?

Technical packaging details often feel overwhelming. Concerns about seam allowance and fabric types cause stress. This delays project launches and confuses the team.

Being a packaging expert is not required. Product dimensions and quantity are sufficient. A professional supplier handles structure, allowances, and material choices.

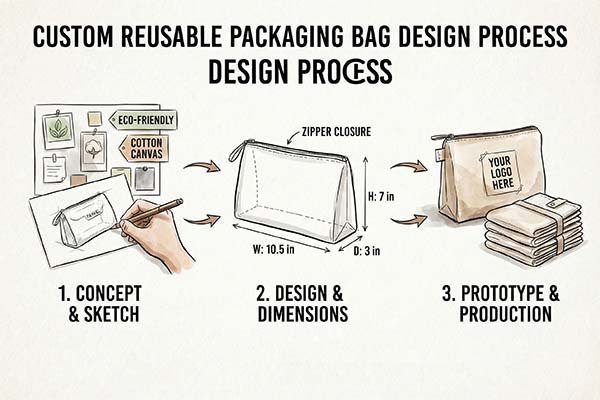

Confusion often arises regarding technical specifications. Clients frequently ask complex questions about patterns or bottom gusset width. These details are not necessary for the brand to figure out. Most brands already possess the product size data. That data is sufficient. If three 50ml bottles are involved, the diameter and height are needed. The supplier handles the rest. Fifteen years of experience in the industry provides the necessary knowledge.

Knowing how canvas behaves is part of the supplier’s role. Calculating how much a zipper shrinks the opening is technical work. Allowances are calculated automatically. The structure is suggested based on the budget and display needs. A flat bag might suit a budget, while a box bottom suits a shelf display. The solution is provided. The product context is the input. This saves time and reduces errors. Materials are also suggested based on this data. Heavy products get thicker canvas. Light products get lighter cotton. The brand focuses on the product. The supplier handles the technical packaging design.

How are eco-friendly toiletry brands and sustainable hotels using reusable packaging bags?

Hotels generate massive amounts of plastic waste daily. Guests notice this wastefulness. It damages the reputation of eco-conscious hospitality brands and alienates modern travelers.

Sustainable hotels replace disposable wrappers with reusable fabric bags. These bags organize amenities, reduce plastic usage, and serve as branded gifts that guests take home.

The hotel industry changes fast. Guests demand eco-friendly stays. Single-use plastic wrappers on combs or toothbrushes are no longer acceptable. Sustainable hotels use многоразовые сумки1 instead. This solves two problems at once. First, waste is cut significantly. A cotton pouch replaces multiple plastic wrappers. Second, luxury is added. A fabric bag feels better than crinkly plastic. This trend is visible in boutique hotels and long-stay apartments.

Hair dryers are placed in nice canvas bags. Toiletries go into washable paper pouches. Guests appreciate this detail. The bag is often taken home. It becomes a souvenir. It reminds the guest of the stay. This serves as great marketing for the hotel. Logistics also benefit. Housekeeping sorts items easily in these bags. Amenity suppliers benefit too. Bundling kits for hotels becomes easier. A reusable bag makes the offer stronger. It helps win contracts with green hotels.

How can reusable zipper bags, drawstring bags, and small tote bags add long-term brand value?

Disposable packaging is a sunk cost that vanishes. The money is paid, and the item goes in the trash. No marketing value remains after the sale.

Reusable packaging extends the life cycle of the brand message. Every time a customer reuses the zipper or drawstring bag, ROI increases through continued visibility.

Packaging is usually just an expense. Payment is made once. It serves one purpose. Then it is gone. Reusable bags change this equation completely. They represent an investment in marketing. A customer buys a travel set. The zipper bag goes to the gym. People at the gym see the logo. The drawstring bag goes to the beach. Friends see the brand name. This constitutes free advertising.

It happens months after the purchase. The bag lasts for years. The brand stays in the customer’s life for years. This improves ROI significantly. It also clarifies the brand story. Claims about caring for the planet require proof. Packaging proves it. Customers trust actions more than words. A cotton bag offers physical proof of values. It creates separation from competitors who still use plastic. Loyalty is built. Customers return because of respect for the brand. This demonstrates the power of reusable packaging.

Заключение

Reusable bags protect products and boost brand value. Switching to cotton canvas or drawstring pouches reduces waste and keeps the brand in the customer’s hands for years.

Frequently Asked Questions

Q: What is the best fabric weight for reusable travel cosmetic bags?

A: For premium travel kits, 8oz to 10oz cotton canvas is recommended. This weight provides enough structure to stand upright on a hotel vanity while remaining flexible enough to pack into crowded luggage without adding unnecessary bulk.

Q: Can the interior be made waterproof to handle potential spills?

A: Yes. Adding a water-resistant lining, such as RPET (recycled polyester) or wipeable nylon, protects the canvas exterior from leaking shampoos or lotions. This feature significantly extends the bag’s lifespan and improves the user experience.

Q: What printing method works best for logos on textured canvas?

A: Silk screen printing is ideal for bold, one or two-color logos as the ink bonds deeply with the fabric fibers. For complex, multi-colored artwork or gradients, digital heat transfer printing ensures high resolution and color accuracy on the textured surface.

Q: Are custom sewn-in wash care labels available?

A: Yes. Including a branded care label is crucial for reusable packaging. It instructs the end-user on how to clean the bag (e.g., cold machine wash, air dry), ensuring the item remains pristine and continues to display the brand logo effectively for years.

Q: How does the choice of zipper material affect the bag’s durability?

A: Metal zippers (brass or antique gold finish) offer a premium look and high durability for luxury sets. However, high-quality nylon coil zippers are smoother around curved corners and are often preferred for lightweight travel pouches to prevent snagging delicate clothing in a suitcase.

Q: Is it possible to see a physical sample before committing to a full production run?

A: Creating a pre-production sample is a standard part of the process. This allows the brand to test the actual fit of the cosmetic bottles inside the bag and verify the fabric texture and print quality before mass manufacturing begins.

Q: Do organic cotton options come with certification?

A: Yes. Bags made from organic materials can be accompanied by GOTS (Global Organic Textile Standard) transaction certificates. This documentation validates the supply chain claims and is essential for brands building a transparent sustainability narrative.

Q: What is the typical lead time for custom reusable packaging orders?

A: Production timelines vary based on complexity and quantity but typically range from 20 to 30 days after sample approval. Factoring in shipping time is essential for aligning packaging delivery with product launch schedules.

Q: Can the drawstring cords be customized to match brand colors?

A: Absolutely. Cotton ropes, ribbons, or herringbone tapes can be dyed to specific Pantone colors. Customizing the drawstring adds a subtle but high-impact branding detail that ties the packaging design together.

Q: How are these bags packed for shipment to the filling facility?

A: To minimize shipping volume and carbon footprint, bags are usually bulk-packed in large cartons. However, for easier distribution at fulfillment centers, they can be bundled in sets (e.g., 50 per pack) or individually wrapped in biodegradable polybags if required.

-

Learn about the advantages of using reusable bags in hotels and how they improve guest satisfaction and reduce waste. ↩