Neoprene bags are popular for promotions, sports, and functional uses, but buying them can be tricky. You might think the biggest risk is the price, but the real problem is often a lack of product knowledge.

Neoprene bags are widely used for laptop sleeves, beach totes, and lunch bags due to their unique feel and insulation. However, buyers frequently misunderstand the difference between water-resistant and waterproof capabilities, as well as the realistic lifespan of the material. This guide clarifies those technical details.

Many buyers place orders based on assumptions rather than facts. They assume the material properties apply to the whole product. Let’s look at the specific mistakes that lead to product failure and how you can avoid them.

What Do Buyers Misunderstand About Neoprene Waterproofing?

You ask suppliers if the bag is waterproof. This seems like a simple "yes or no" question, but the answer often leads to disappointment when the product arrives.

Buyers often confuse the properties of the raw material with the performance of the finished bag. While neoprene rubber itself does not absorb water, most standard neoprene bags are only water-resistant. This means they can handle light rain but will leak if submerged or exposed to heavy water.

To understand this better, we must separate the material from the product construction. Neoprene1 is a closed-cell foam. This means the material itself is a barrier. If you pour water on a sheet of neoprene, it will not pass through. This leads many buyers to believe the final bag will be fully waterproof2.

However, a bag is not just a sheet of material. It has seams, zippers, and pockets. In standard manufacturing, we use needles to stitch the bag together. Every time the needle passes through the neoprene, it punches a tiny hole. If you throw the bag into a pool, water will rush in through these needle holes.

Also, the outer layer matters. Neoprene is usually laminated with fabric like polyester or jersey to make it look good. This fabric layer can get wet and hold water, even if the rubber inside stays dry.

| Caratteristica | Material Property | Finished Bag Reality |

|---|---|---|

| Water Barrier | 100% impermeable | Leaks through seams |

| Surface | Rubber repels water | Fabric layer gets wet |

| Main Use | Diving / Wetsuits | General protection |

Therefore, when you search for keywords like "neoprene waterproof," remember that a "waterproof material" does not automatically equal a "waterproof bag."

Why Is Water-Resistant Not the Same as Waterproof?

You might wonder why a material used for wetsuits leaks when made into a tote. The difference lies in how we put the pieces together during manufacturing.

Water-resistant bags repel water from the surface for a short time, while waterproof bags are sealed to prevent any entry. The difference comes from construction details like taped seams, waterproof zippers, and specific sealing methods that are far more expensive than standard sewing.

The term "water-resistant" means the bag can resist the penetration of water to some degree but not entirely. For standard neoprene bags, we use regular zippers and standard stitching. This is perfectly fine for a lunch bag or a laptop sleeve. It protects against spills or light drizzle.

To make a bag truly "waterproof," we need completely different technology. We cannot use standard sewing machines. We must use high-frequency welding or apply waterproof tape over every single seam to seal the needle holes. We also need to use airtight zippers, which are much stiffer and more expensive than regular zippers.

Many buyers do not understand this cost difference. They ask for a cheap promotional bag but expect the performance of a high-end dry bag. If you market a standard water-resistant neoprene bag as "waterproof," your customers will complain when their items get wet during a heavy storm.

Correct expectations are vital. A water-resistant neoprene bag is durable and protective, but it is not a submarine. Understanding the construction limits helps you manage your customer’s expectations and reduces after-sales risks.

How Long Do Neoprene Bags Last in Real Use?

You want to know exactly how many years these bags will last. However, getting a single number from a factory is difficult because every user treats the product differently.

There is no single expiration date for a neoprene bag. Its lifespan depends entirely on the usage scenario. A promotional gift used once a month will last much longer than a gym bag used daily. Frequency of use impacts durability more than the age of the material.

We need to break down the lifespan based on how the bag is actually used. There is no standard "3-year guarantee" that fits every situation.

First, consider promotional items. If a neoprene pouch is used to hold a gift and then sits in a drawer, it can last for many years. The material is stable. However, if that same bag is a tote used for daily grocery shopping, the lifespan changes. Daily friction wears down the fabric surface. Heavy loads stretch the foam.

Second, consider the environment. Neoprene is sensitive to UV light and chemicals. A beach bag exposed to hot sun and saltwater every day will age faster than a laptop sleeve kept inside an office. The sun can cause the color to fade and the rubber to become brittle over time.

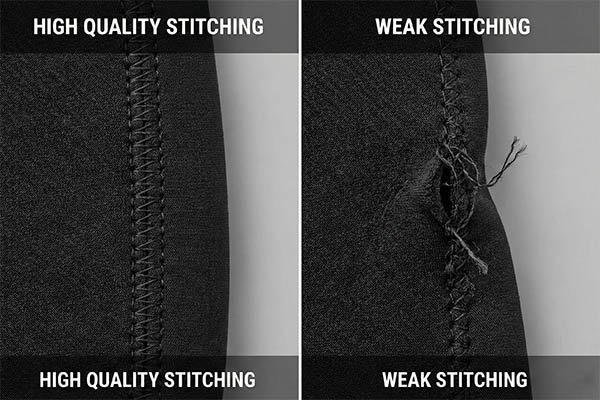

Third, look at the components. Often, the neoprene body is fine, but the zipper fails or the stitching unravels due to stress. This is why I tell clients that usage frequency is more important than the material itself. A durable neoprene bag is designed for the specific stress it will encounter. If you use a thin cosmetic bag structure for a heavy gym bag, it will fail quickly, not because the neoprene is bad, but because the application is wrong.

What Affects the Real Lifespan of Neoprene Bags?

You cannot control how a customer uses the bag. However, you can control the manufacturing quality to ensure the bag survives normal wear and tear.

The lifespan is determined by material density, lamination quality, and structural design. Choosing the right thickness and high-quality nylon lamination prevents the bag from losing its shape. Weak stitching or low-density foam will cause the bag to fail prematurely.

This is where the technical choices you make during sourcing become critical. Many sourcing mistakes happen here because buyers focus only on price or simple thickness (mm).

1. Material Grade (SBR vs. CR):

Not all "neoprene" is the same. Real neoprene (CR) is expensive. Most promo bags use SBR (Styrene Butadiene Rubber) or a blend. Cheap SBR is stiffer and ages faster. If you buy the cheapest option, the foam may harden and crack within a year. You must specify the grade.

2. Density vs. Thickness:

Buyers often ask for "3mm thickness." But 3mm of low-density foam feels like a soft sponge. It offers no support. A bag made of this will sag and look cheap. You need high-density foam to keep the bag’s shape. A thinner, high-density foam is often better than a thick, low-density one.

3. Lamination Quality:

Neoprene is a sandwich. The rubber is in the middle, with fabric glued on both sides. If the glue is bad, or the lamination process is rushed, the fabric will peel off. This is called delamination. It looks like bubbles on the bag. Also, the choice of face fabric matters. Basic polyester pills (gets fuzzy balls) easily. Nylon is stronger and smoother but costs more.

4. Structural Design:

If you put heavy metal hardware on thin neoprene without reinforcement, it will tear. You need to reinforce stress points.

| Fattore | Low Quality Risk | High Quality Solution |

|---|---|---|

| Materiale | Pure SBR (Cracks early) | SBR/SCR Blend |

| Density | Soft, loses shape | Firm, holds shape |

| Lamination | Peeling fabric | Strong bond glue |

How Can Buyers Avoid Sourcing Mistakes in China?

You do not want to find out about these problems after the goods arrive. The best way to secure your investment is to ask the right questions before production begins.

To avoid sourcing mistakes, clearly define your usage scenario to the supplier. Do not just ask for "neoprene"; specify the density and fabric type. Always request a physical sample to test water resistance and structural strength before approving the bulk order.

The key to successful sourcing is communication. You must go beyond asking "How much?" and start asking "How is it made?".

First, be honest about the end use. Tell us if this is a cheap giveaway or a premium retail product. If we know it is for retail, we will suggest better lamination and higher density foam. If it is a giveaway, we can cut costs on the internal foam while keeping the outside looking good.

Second, do not guess the specs. Ask your supplier for options. Ask them: "What is the difference in hand-feel between these two foams?" or "Will this print fade in the sun?" A good supplier wants to explain these limitations to you. We prefer to explain now rather than apologize later.

Third, always test the sample. When you get the prototype, load it with weight. Carry it around. Splash water on it. See how it behaves. If the handle stretches too much, we need to add stitching reinforcement. If the water soaks in too fast, we might need a water-repellent coating on the fabric.

As a supplier, I always advise: Say "no" to bad quality early. It is much easier to fix a spec sheet than to fix a container of defective bags. By understanding the materials and the process, you protect your brand and your budget.

Conclusione

Sourcing neoprene bags requires more than comparing prices; you must understand material density, waterproofing limitations, and construction methods to ensure the final product meets your customers’ real-world needs.

Frequently Asked Questions

Q: My customers often complain about a strong rubber smell when opening new neoprene bags. Is this toxic, and how can we remove it?

A: The smell is natural to the manufacturing process of synthetic rubber and adhesives. It is generally not toxic if the material passes REACH or CA65 standards. To reduce it before retail, we recommend airing the bags out in a ventilated area for 48 hours before final packaging, or using odor-absorbing silica gel packets inside the polybag.

Q: Can neoprene bags be customized with full-color photos or complex patterns?

A: Yes, but the method matters. For complex, multi-colored designs, we recommend Sublimation Printing. This fuses the ink into the polyester face fabric so it won’t crack or peel. Silk screen printing is better for simple, bold logos (1-2 colors) but struggles with gradients or photo-realistic images.

Q: If neoprene arrives creased or folded in the shipping carton, is the product ruined?

A: Not necessarily. Neoprene has memory, but deep creases can be stubborn. We advise packing bags flat whenever possible. If creases occur, they can often be relaxed by steaming the bag gently (not ironing directly) or letting it hang in a warm room. Permanent creases usually indicate the foam density was too low.

Q: Is neoprene actually eco-friendly?

A: Traditional neoprene is petroleum-based, so it is not biodegradable. However, we can source "Eco-Neoprene" (Limestone-based) or Recycled Neoprene (RPET laminated onto the foam) to meet sustainability goals. These options cost more but are excellent for eco-conscious brands.

Q: Does the thickness of the neoprene affect its insulation properties for lunch bags?

A: Yes. Thicker neoprene traps more air bubbles, which provides better thermal insulation. For a high-quality lunch bag meant to keep food cold for hours, we recommend at least 4mm thickness. 3mm is standard for cosmetic bags but offers less thermal retention.

Q: Are there compliance standards I should check for when importing neoprene to the US or EU?

A: Absolutely. Since neoprene uses glues and dyes, you must ensure the product is free from harmful phthalates, heavy metals, and AZO dyes. Always ask your supplier for current SGS or Intertek test reports verifying compliance with California Prop 65 (for the US) or REACH (for Europe).

Q: Can I machine wash neoprene bags?

A: We recommend hand washing and air drying to prolong the lifespan. While neoprene itself handles water well, the agitation of a washing machine can damage the lamination glue or cause the outer fabric to pill over time. If machine washing is a "must-have" selling point, we need to use higher-strength lamination adhesives.

Q: Why do I see such a huge price difference between two "neoprene" quotes?

A: Apart from SBR vs. CR grades, the price difference often comes from the "filler" in the rubber. Cheaper factories add high amounts of calcium powder to the rubber mix to cut costs. This makes the bag heavier and more prone to cracking. A lighter bag usually indicates purer rubber and better quality.

Q: Can we Pantone match the neoprene fabric color?

A: We match the tessuto laminated on top, not the rubber itself (which is usually black or beige). We can dye the polyester face fabric to your specific Pantone (PMS) color. However, keep in mind that neon colors may fade faster in sunlight compared to standard darker tones.

Q: What is the typical tolerance for neoprene thickness in production?

A: In the industry, a tolerance of ±0.5mm is standard. If you order 3mm neoprene, the actual thickness might range from 2.5mm to 3.5mm after lamination and compression. If your product requires exact precision (e.g., for a tight electronic device fit), we must specify a "strict tolerance" grade, which costs slightly more.