Many wholesale buyers struggle to choose the right leather material for their custom bags. If you pick the wrong material, you might face high costs, quality issues, and customer complaints later.

For most wholesale orders, PU leather offers the lowest upfront cost, making it ideal for budget projects. However, microfiber leather often provides better long-term value because of its durability and stability. Genuine leather suits high-end brands where longevity justifies the high price.

You might think the lowest price is always the best choice for your business. Let us look at why the cheapest price can actually cost you more money later.

Why Cost-Effective Matters More Than Low Price in Wholesale?

Buyers often focus only on the unit price per bag during the negotiation. This approach often leads to unexpected problems during mass production and international shipping.

True cost-effectiveness includes the material price and the risk of defects. In wholesale, hidden costs like rework, delayed delivery, and customer returns often cost more than the raw material savings. Stability reduces these expensive risks.

In my 15 years of experience with B2B orders, I have seen many buyers make a common mistake. They choose the cheapest material to save money on the unit cost. But "cost-effective" is not the same as the "lowest price." When you manage a supply chain, you must look at the total cost of ownership. The unit price of the material is just one part of the equation.

You must also consider the hidden costs in mass production. If the material is cheap but unstable, the factory may need to rework the products. This causes delays in your lead time. If the quality varies between batches, your customers might return the goods. A high return rate damages your brand reputation. For a procurement manager, a stable material protects you from these risks. We believe that paying a little more for a stable material is better than paying for air freight to fix a delay. Cost control is about reducing risk, not just cutting the material cost.

What Leather Options Are Common for B2B Wholesale Orders?

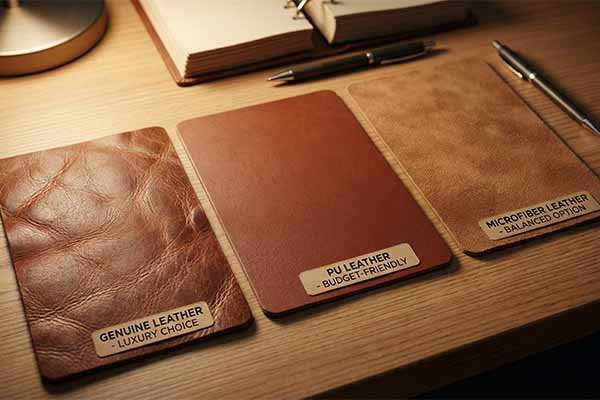

You will see three main types of leather in the market for custom bags. Knowing the difference helps you make the right purchasing decision for your specific project.

The three common options are Genuine Leather, PU Leather, and Microfiber Leather. Genuine leather is for luxury items. PU leather is the most affordable and common. Microfiber leather sits in the middle and offers a strong balance of price and quality.

When we discuss wholesale orders, we must look at these materials based on their feasibility for mass production. We do not just look at which one feels the most expensive.

First, you have Genuine Leather1. This is natural skin. It positions your product as high-end. However, it represents the highest cost tier. The shape of natural hides is irregular. This leads to a lot of waste during cutting. It is hard to keep every bag looking exactly the same.

Second, you have PU (Polyurethane) Leather2. This is a synthetic material. It represents the most budget-friendly entry point. It is the most widely used material in the bag industry. The quality can vary a lot depending on the factory.

Third, you have Microfiber Leather. This is a high-tech synthetic leather. It mimics the structure of real leather. The cost sits in the middle ground. It is higher than standard PU but significantly more accessible than genuine leather. It offers high stability for large B2B projects. It is becoming very popular for brands that want quality without the high price of real leather.

How Does PU Leather Perform in Large-Volume Orders?

PU leather is the most common choice for large orders and promotional items. Many buyers choose it because it fits tight budgets easily and offers many colors.

PU leather excels in cost and production speed. It is the most economical option on the market. It is perfect for seasonal items or promotions. However, you must control the quality strictly to avoid peeling issues.

If your main goal is to keep the unit price as low as possible, PU leather is your best option. It is the absolute cheapest material available for bag manufacturing. This low barrier to entry makes it very attractive for fast-fashion brands, gift companies, and seasonal products. The production cycle for PU is fast and simple. This helps if you have a tight deadline.

However, you must be careful with the quality. PU leather generally has a shorter lifespan than other materials. It can peel or crack over time. This is known as hydrolysis3. Cheap PU can also have a strong chemical smell. If you choose PU, you need a supplier who performs strict quality control. You must ensure the thickness and backing are correct for your specific bag design. PU leather is cost-effective only when the quality matches the intended use of the product. Do not use it for products that need to last for many years. It is a tool for volume, not longevity.

Why Is Microfiber Leather a Stable Choice for B2B Projects?

Some projects require better quality and durability than standard PU can provide. Microfiber leather is becoming the preferred choice for serious brands and long-term sellers.

Microfiber leather costs more upfront but offers excellent batch stability. It resists peeling and holds printing logos well. For long-term B2B projects, it reduces the defect rate significantly, making it a smarter investment than cheap PU.

Microfiber leather commands a higher price than standard PU. It requires a larger initial investment from the buyer. However, the performance justifies the cost. For a B2B buyer, stability is key. Microfiber leather has a uniform structure. It does not have the natural defects of genuine leather. This means we can cut it efficiently with almost zero waste.

It is also very strong. It resists tearing, abrasion, and peeling much better than PU. If your brand sells mid-to-high-end bags, this material feels very close to real leather. It also handles processes like logo printing, embossing, and sewing very well. The defect rate in production is extremely low. This means fewer surprises for you when you inspect the goods. For long-term repeat orders, Microfiber leather ensures that the bag you sell today looks the same as the bag you sell next year. This consistency builds trust with your customers. The savings come from reliability, not just the sticker price.

What Leather Material Fits Different Wholesale Use Cases?

Every project has specific needs, target audiences, and budget limits. Matching the material to the actual use case saves you time and money.

Use PU leather for promotional gifts and short-term items. Choose microfiber leather for custom retail bags and packaging that need durability. Select genuine leather only for high-end luxury products where price is not the main concern.

You can use this simple guide to make your decision. We advise our clients to look at the product lifecycle.

If you are buying for a promotional event or a free gift with purchase, choose PU leather. The cost is minimal. The product only needs to last for a short season. The visual effect is good enough for a giveaway.

If you are a retail brand or an e-commerce seller, consider Microfiber leather. Your customers expect the bag to last. They will complain if the material peels after a short time. Microfiber gives you a premium feel and high durability. It protects your brand image.

If you are positioning your brand as a luxury line, you may need Genuine Leather. Customers pay a premium price for the "authentic" label and the smell of real leather. In this case, the high material cost is part of the value proposition.

Here is a quick comparison for your decision:

| Aspetto | PU Leather | Microfiber Leather | Genuine Leather |

|---|---|---|---|

| Upfront Price | Lowest (Best for budget) | Medium (Worth the investment) | Highest |

| Durata | Da basso a moderato | High (Resists peeling) | Very High (Ages well) |

| Il miglior caso d'uso | Seasonal / Promo Gifts | Retail Brands / Daily Use | Luxury / High-End |

Conclusione

Choosing the right material depends on your balance of risk and cost. PU is for budgets, microfiber is for stability, and genuine leather is for luxury.

Frequently Asked Questions

Q: Can PU and Microfiber leather pass environmental tests like REACH or CA Prop 65?

A: Yes, both synthetic options can be manufactured to meet strict environmental standards. However, "eco-friendly" grades use different chemicals than standard stock, so you must specify these testing requirements in your tech pack before quoting, as it affects the raw material cost.

Q: Which material is the easiest to color match with a specific Pantone code?

A: Microfiber and PU leather are the easiest to match because they are synthetic and produced in controlled dye lots. Genuine leather absorbs dye differently depending on the hide’s porosity, making exact Pantone matching difficult and often requiring a tolerance range.

Q: Does the choice of leather affect the shipping weight and logistics costs?

A: Yes. Genuine leather is significantly heavier than synthetic options. For large wholesale orders, switching to Microfiber or PU can reduce the gross weight of the shipment, lowering your air or sea freight costs per unit.

Q: How does humidity during ocean freight affect these materials?

A: Standard PU leather is susceptible to hydrolysis (peeling) if exposed to high heat and humidity in a shipping container for weeks. If your supply chain involves long ocean transit, we recommend adding desiccants or choosing hydrolysis-resistant Microfiber to prevent damage upon arrival.

Q: Is there a difference in the Minimum Order Quantity (MOQ) between these materials?

A: Generally, synthetic leathers (PU and Microfiber) require a higher material MOQ (often 300-500 meters) if you need a custom color because factories must run a full production line. Genuine leather can sometimes be purchased in smaller quantities if stock hides are available, though the unit price will be higher.

Q: Which material holds embossed logos better?

A: Microfiber leather and Genuine leather hold deep embossing (debossing) very well because of their dense fiber structure. Thin or low-quality PU leather may not hold a crisp logo shape for long and can sometimes bounce back or look shallow.

Q: Can I change the backing fabric of the synthetic leathers?

A: Yes. Both PU and Microfiber allow for different backing options (such as woven, non-woven, or fleece). Changing the backing changes the "hand feel" and structure of the bag—making it slouchy or stiff—without changing the external look.

Q: Do these materials have different lead times for production?

A: Synthetic materials usually have a shorter and more predictable lead time (15–20 days) as they are manufactured on demand. Sourcing specific genuine leather hides can take longer (30+ days), especially if they need to be imported or tanned to a specific finish.

Q: How do I handle the strong smell often associated with synthetic leather?

A: Strong chemical odors usually come from low-grade adhesives in cheap PU. To avoid this, request "low-odor" or water-based eco-friendly PU. A good manufacturer will also air out the material in the warehouse before cutting and sewing to ensure the final product is odorless.

Q: Are these materials waterproof?

A: PU and Microfiber are naturally water-resistant and easy to wipe clean because they are plastic-based. Genuine leather is porous and absorbs water, which can cause staining or stiffening unless it is treated with a specific water-repellent coating.

-

Explore the advantages of Genuine Leather to understand its value and why it’s considered high-end. ↩

-

Learn about PU Leather’s budget-friendly nature and its widespread application in the bag industry. ↩

-

Learn about hydrolysis and its impact on PU leather quality to ensure your products meet durability standards. ↩