Many businesses panic when they see the final quote for custom bags. You plan a budget, but hidden fees and complex add-ons suddenly eat your profit margin.

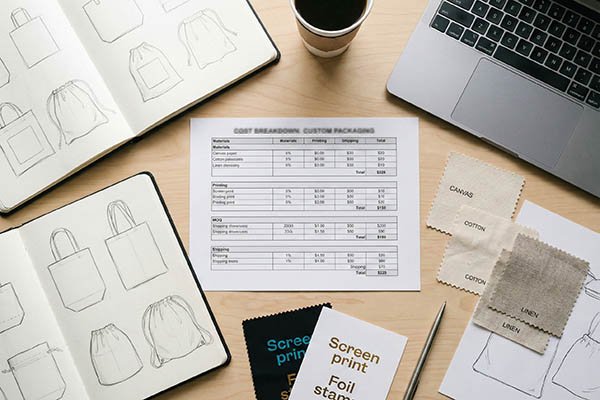

Custom bag costs go beyond just the product price. The final quote depends on five key factors: material choice, bag complexity, printing methods, order quantity (MOQ), and shipping logistics. Understanding these helps you control your budget and avoid surprise fees.

Buying standard stock bags is simple. You pay the price you see. Custom projects are different. Every design choice changes the price. Let’s look at what you are actually paying for.

What Key Factors Decide the Final Price of Custom Bags?

You see a base price on a website, but the final invoice looks very different. Why does the price change so much from the initial estimate?

The price of a custom bag comes from five main areas: raw materials, labor and craftsmanship, printing costs, shipping fees, and taxes. Each step of the custom process, from design to final packaging, adds specific costs to your total bill.

Standard bags use fixed designs, so the cost is stable. Custom bags are different. You build the cost from the ground up. The foundation is the raw material. This usually takes up 30% to 40% of the total price. Then you have labor. Cutting, sewing, and printing take up another 20% to 30%. Hardware like zippers and buckles adds another 10% to 15%.

But you must look at the process fees too. Customization creates "invisible" costs. Design work happens before production starts. You might pay for a sample to check the quality. This is a separate cost. During mass production, quality control1 is essential. We check every bag to avoid defects. This adds to the labor hours.

Factories quote prices differently. One factory might include packaging in the unit price. Another might charge for packaging separately. You need to ask for a full breakdown2. Check if the price includes the "hidden" steps. Look at the design fee, the sample fee, and the packing fee. This helps you judge if a quote is reasonable. You can compare apples to apples this way.

| Cost Component | Approximate % of Total | What is included? |

|---|---|---|

| 자료 | 30–40% | Fabric, lining, handles, labels |

| Labor | 20–30% | Cutting, sewing, printing, QC |

| 하드웨어 | 10–15% | Zippers, buttons, metal rings |

| Overhead | Remaining | Packaging, compliance, profit |

How Do Materials and Bag Styles Influence Your Overall Cost?

You want a premium look for your brand, but you also have a strict budget. How do you choose materials that look good without overspending?

Materials are the biggest part of your cost. Premium options like heavy canvas, RPET, or Tyvek cost more than standard cotton. Complex shapes with pockets or zippers also increase labor time, which raises the price per unit significantly.

Your choice of fabric sets the baseline price. Standard cotton is affordable and popular. If you choose heavy canvas, the material cost goes up. Special materials cost even more. For example, RPET is made from recycled plastic bottles. It is eco-friendly, but the processing is expensive. You also pay for certifications like GRS (Global Recycled Standard). Tyvek is durable and waterproof, but it is a patented material, so it is not cheap.

The shape of the bag matters just as much as the fabric. A flat tote bag is the cheapest style. It requires simple cutting and straight sewing. If you add a bottom gusset or side gussets, you use more fabric. You also add more sewing steps. A 3D box shape takes longer to stitch than a flat bag.

Details add up quickly. Every zipper, pocket, or lining layer adds cost. A bag with an inner pocket needs extra fabric and extra labor time. If you want a full lining, you are essentially making two bags and sewing them together. This doubles your material usage. For small businesses, we suggest balancing the look with the cost. You can choose a high-quality fabric but keep the shape simple. Or you can choose a complex shape but use standard cotton. This keeps your brand image high but your costs low.

Why Minimum Order Quantities Change Your Unit Pricing?

Small businesses often struggle with high minimum order requirements from factories. Why does buying fewer bags make each bag so much more expensive?

Factories have fixed costs for every order, like machine setup and pattern making. When you order a large quantity, these costs spread out. With a small order, you pay a larger share of these fixed costs per bag.

In manufacturing, we call this "economies of scale." Every time we start a new order, we have startup costs. We have to set up the printing screens. We have to calibrate the cutting machines. We have to buy the specific fabric. These are fixed costs. They cost the same whether you order 100 bags or 10,000 bags.

Let’s look at the math. Imagine the setup cost is $100. If you order 100 bags, that setup adds $1 to every bag. If you order 1,000 bags, that setup only adds $0.10 to every bag. This is why the unit price drops when you order more. Large orders also let us buy fabric in bulk. Fabric suppliers give us discounts for big rolls. We pass these savings to you.

Small orders are risky for factories. The labor time to organize a small order is almost the same as a big order. To cover this, factories charge a higher unit price for small batches. This protects their margin.

For a small business, you need a strategy. You can start with a "standard product + small print" approach. You buy a stock bag that is already made. Then we just print your logo on it. This avoids the custom manufacturing setup fees. It is the most cost-effective way to test your market. Once your sales grow, you can move to fully custom orders to get a lower unit price.

What Printing Options Give You the Best Value for Branding?

A colorful logo looks great, but complex designs can double your production cost. How do you pick a printing method that fits your budget?

Printing costs depend on the number of colors and the method used. Silk screen printing is cheap for simple logos. Digital printing works best for photos but costs more. Watch out for hidden fees like mold charges or color matching fees.

Your logo design directly impacts your wallet. The most common method is silk 스크린 인쇄. It is durable and affordable. But, we charge by the color. If your logo has one color, you pay for one screen. If your logo has four colors, you pay for four screens. You also pay for four printing passes. This multiplies your cost.

For complex images, like a photo or a gradient, screen printing is not a good choice. We use digital printing or heat transfer instead. These methods can print millions of colors at once. The setup is easier, but the ink is more expensive. For large areas of full-color printing, the price is high. Embroidery is another option. It looks premium and lasts a long time. However, we price embroidery by the number of stitches. A large, solid logo takes thousands of stitches and a long time on the machine.

You must watch out for hidden fees in printing. "Plate fees" or "mold fees" are one-time costs to make the printing template. If you change your design, you pay this fee again. There are also color proofing fees. If you need an exact Pantone color match, we have to mix ink specially. This takes time and costs money.

To save money, simplify your logo for the bag. A single-color logo on a natural canvas bag looks very elegant. It is cheaper to produce and often looks more professional than a messy, multi-color print.

How Can You Calculate Shipping, Duties, and Other Hidden Costs?

You pay the supplier, but then you get a surprise bill from the logistics company. How do you predict the total landed cost of your goods?

International shipping methods vary greatly in price. Air freight is fast but expensive. Sea freight is slow but cheap. You must also budget for import duties, taxes, and hidden fees like special packaging or remote area surcharges.

Shipping is often the biggest shock for new buyers. You have two main choices: air or sea. Air freight is fast. It takes about 5 to 10 days. But it costs a lot. It is calculated by weight. If your bags are light but bulky, airlines charge by "volume weight." This means you pay for the space you take up, not just the heaviness. Sea freight is much cheaper. It is the best choice for bulk orders. But it takes 30 to 45 days. You need to plan your timeline carefully.

You must also calculate taxes. When goods enter your country, the government charges import duties. The rate depends on the material. Cotton bags have a different tax rate than polyester bags. You also have to pay VAT or sales tax. These are not usually included in the factory price.

There are other small costs that add up. Special packaging is one. If you want each bag in a separate plastic bag, that costs extra labor and material. It also adds weight to the shipment. If your delivery address is in a residential area or a remote town, couriers charge a "remote area surcharge."

We recommend asking for a "DDP" price (Delivered Duty Paid). This means the supplier handles shipping, taxes, and delivery. You pay one final price. It removes the risk and makes budgeting much easier for you.

결론

Cost isn’t just the bag price. You must plan for materials, labor, printing, quantity, and logistics. Proper planning prevents budget surprises and ensures your custom bags arrive on time and within your profit margin.

Frequently Asked Questions

Q: If I place a second order with the same design, do I have to pay the mold or setup fees again?

A: Typically, no. Most factories keep your printing screens or molds on file for a certain period (usually 6 to 12 months). If you reorder the exact same design within that timeframe, you save on those setup costs, making the unit price slightly lower for repeat orders.

Q: Is the sample fee refundable if I decide to proceed with bulk production?

A: Yes, in many cases. If your bulk order meets a specific quantity threshold (for example, over 1,000 pieces), the factory will often deduct the initial sample fee from your final invoice, essentially making the sample free.

Q: Can I mix different fabric colors to meet the Minimum Order Quantity (MOQ)?

A: Usually, no. The MOQ is tied to the fabric dyeing process. Since the fabric factory requires a minimum amount to dye a specific color run, you typically need to meet the MOQ per color (e.g., 500 green bags, not 250 green and 250 blue).

Q: How much extra does it cost to use branded hardware like YKK zippers instead of standard ones?

A: Using famous brands like YKK can increase the hardware cost by 2 to 3 times compared to generic unbranded zippers. While this raises the unit price, it significantly increases the durability and perceived value of the bag for retail brands.

Q: Do you charge extra for sticking barcodes or Amazon FBA labels on the packaging?

A: Yes, there is usually a small labor fee per unit for applying individual stickers or hangtags, as this slows down the final packing line. However, this is much cheaper than having to label them yourself after delivery.

Q: What is the standard payment term for a custom order?

A: The industry standard for international B2B trade is a 30% deposit to start production (purchasing materials) and the remaining 70% balance paid before shipment. This ensures commitment from both the buyer and the manufacturer.

Q: Does the "Unit Price" usually include shipping insurance?

A: No, standard quotes often exclude insurance unless you request CIF (Cost, Insurance, and Freight) terms. Adding insurance is relatively cheap (often around 0.1-0.3% of the cargo value) and is highly recommended to protect against loss or damage during ocean transit.

Q: If I provide my own design file, does the format affect the cost?

A: Indirectly, yes. If you provide a low-quality JPEG, the factory’s design team has to redraw it into a vector format (AI or PDF) for printing, which may incur a "design repair" fee. Providing high-quality vector files upfront avoids these extra labor charges.

Q: Is there a cost difference between "spot goods" (stock bags) and "custom-made" bags regarding lead time?

A: Yes. "Spot goods" only incur a printing cost and can ship in a few days. Fully custom-made bags require weeks for material procurement and sewing. If you need custom bags rushed faster than the standard timeline, factories may charge a "rush fee" to cover overtime labor.

Q: Can I hire a third-party inspection company to check the goods before I pay the balance?

A: Absolutely. While this is an additional cost you pay directly to the inspection agency (not the factory), it is a valuable investment for large orders. It ensures the quality matches your sample before the goods leave the factory floor.