Are you struggling with rising production costs and low profit margins on your bag orders? Many buyers focus only on the unit price and ignore how leather choices impact the total budget.

Leather choice determines your material cost, labor expense, and production scale. Choosing the right material like PU or microfiber helps control waste and manufacturing speed. This balance is essential for maintaining a stable supply chain and achieving your target retail price points.

Selecting the wrong leather can lead to unexpected expenses and quality issues that hurt your brand. Many procurement managers believe that choosing a more expensive material always results in a better product for their customers. However, high-end materials often come with hidden costs like higher waste rates and slower production times. You need to understand how each leather type functions in a B2B environment to make the best decision. If you pick a material that does not fit your project goals, you will face inconsistent quality and late deliveries. This guide explains how to match leather types to your specific business needs to save money and time.

WHAT Leather Options Are Commonly Used in Wholesale Bags?

Do you know which synthetic or natural leathers actually fit your specific production volume and budget requirements? Choosing a material without knowing its industrial properties often leads to high scrap rates and manufacturing delays.

Common leather options include PU, microfiber, and natural hides, each serving different price points and durability needs. Standard PU is the most frequent choice for promotional items, while microfiber offers a premium feel for retail brands.

In the world of B2B procurement, we group leather into categories based on their chemical composition and performance. Most wholesale projects use synthetic options because they offer better consistency across large batches. You must choose based on how the end-user will interact with the product. As a supplier with 15 years of experience, I see that selecting "suitable" leather is always better than just "expensive" leather.

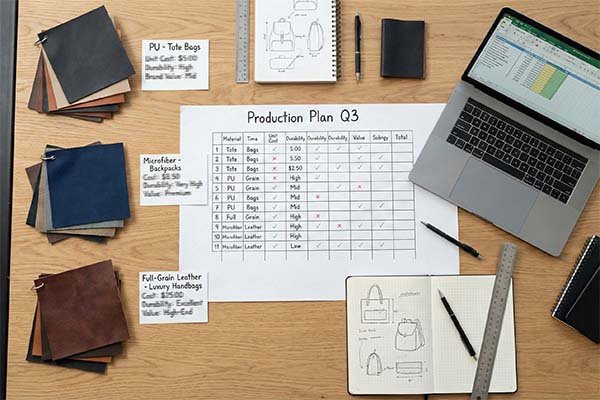

Comparison of Common Wholesale Materials

| نوع المادة | حالة الاستخدام الشائع | Cost Level | Consistency |

|---|---|---|---|

| Standard PU | Giveaways, low-cost retail | Entry-level | عالية |

| ألياف دقيقة | Premium bags, laptop cases | Mid-range | عالية جداً |

| Silicone Leather | Eco-friendly, baby products | Premium Synthetic | عالية |

| Natural Leather | Luxury goods, boutique brands | High-end | متغير |

Standard PU is very popular because it is easy to source and comes in many colors. Microfiber is a newer choice that mimics the feel of real leather but stays very durable. For brands focusing on sustainability, silicone leather is an emerging option. Natural leather remains the top choice for luxury, but it requires much stricter quality control. You should look at your target market before deciding on the material grade.

WHY PU Leather Is a Cost-Effective Choice for Many B2B Projects?

Are you worried that using PU leather will make your brand look cheap to your target customers? Many successful brands use high-quality PU to maintain competitive prices while still offering a product that looks professional and stylish.

PU leather is cost-effective because it has a stable price and creates very little waste during the cutting process. It allows for faster production and more flexible order requirements compared to specialized natural leather hides.

I often tell my clients that PU is a smart cost management tool rather than just a cheap substitute. In mass production, you need materials that behave the same way every time. PU leather comes in rolls with a fixed width, which makes it very easy to plan the cutting layout. This efficiency reduces the amount of fabric you throw away. It is a stable and replicable solution that balances cost and brand effect.

Operational Advantages of PU

- Price Stability: Synthetic materials do not fluctuate in price as much as animal hides do.

- Low Waste: Since rolls are uniform, you can use nearly all of the material you buy.

- Easy Decoration: PU works well with silk screening, heat transfer, and embossing without damaging the surface.

- Lead Times: Factories can source standard PU colors quickly, which helps you meet tight deadlines.

Because PU is man-made, we can control the thickness and the texture perfectly. This means the first bag in your order will look exactly like the last bag. For procurement managers, this predictability is the best way to avoid complaints about inconsistent quality between batches. It solves the pain point of quality variance often found in natural materials.

HOW Different Leather Types Impact Unit Cost and MOQ?

Is your current supplier asking for high minimum orders that lock up too much of your company capital? The material you choose dictates how much money you must spend upfront and how many units you must buy.

Material choice shifts the cost focus from labor to raw inputs. Synthetic leather generally offers a lower entry cost and more accessible order minimums, while genuine leather requires a significant investment in raw hides.

When you use synthetic leather, the raw material is often a smaller part of the total price. This means most of your money goes toward labor, hardware, and branding. However, with natural leather, the material itself becomes the biggest cost driver. You also have to consider the "yield." Natural hides have scars and irregular shapes, so you might lose a large portion of the material during cutting. This increases the effective cost per usable area significantly.

Cost and Logistics Breakdown

| الميزة | Artificial Leather (PU/PVC) | Natural Leather (Hides) |

|---|---|---|

| Capital Investment | Lower per project | Significant upfront cost |

| Order Minimums | More flexible for customization | Often high due to hide sizes |

| Waste Rate | Minimal (uniform rolls) | High (natural defects) |

| Labor Intensity | Lower (automated cutting) | Higher (manual selection) |

A bag made of PU keeps your unit cost manageable, while the same bag in real leather could multiply the price just for the raw material. This gap affects your wholesale strategy. If you want to sell large volumes, synthetic leather is the best way to keep the price accessible. Natural leather is better for high-margin, low-volume boutique sales where buyers accept a premium price point.

HOW to Match Leather Quality with Budget Without Over-Specifying?

Are you spending too much on high-spec materials that your customers do not actually need or appreciate? Over-specifying happens when you choose expensive materials for a product with a short life cycle, like a gift bag.

To match quality with budget, you must analyze the expected life of the product and its primary function. Focus your spending on the parts of the bag that experience the most stress and wear.

I see many buyers make the mistake of asking for the thickest leather possible for a simple promotional pouch. This raises the shipping weight and the material cost without adding real value. You should work backward from your target price. If you have a strict budget, use a standard PU for the body but spend a little more on reinforced handles or better zippers. This is how we provide solutions that balance delivery efficiency and brand presentation.

How to Allocate Your Budget

- Identify Stress Points: Put better material or reinforcement on handles and corners.

- Check Life Expectancy: Use basic materials for events and high-grade microfiber for retail laptop bags.

- Visual Impact: Use premium textures only on the front panel where the customer sees it first.

- Weight Limits: Choose lightweight synthetics if the bag needs to carry heavy items to avoid adding extra bulk.

By focusing on structure rather than just the "premium" label of the leather, you get a better product. A well-designed bag made from mid-grade PU often lasts longer than a poorly made bag using thin genuine leather. This approach helps you maintain quality while keeping your finance team happy and avoiding unexpected cost increases.

WHAT Leather Choice Makes Sense for Your Actual Use Case?

Do you have a clear list of requirements to help you decide which material will lead to the best return on investment? Making a choice based on "feel" alone often leads to budget overruns and unhappy customers who expected different performance.

The right choice depends on whether you are doing a one-time promotion or building a long-term retail brand. You must weigh the importance of unit cost against the value of brand perception and durability.

If you are a marketing manager for a gift company, PU is almost always the winner because it is versatile and budget-friendly. If you are a founder of a startup selling to high-end professionals, you might need microfiber or natural leather to justify your brand positioning. Always ask yourself: "How often will the customer use this bag?" and "What is the maximum price they will pay?". My insight is that choosing the "right" leather is more important than choosing "expensive" leather.

Decision Checklist for Procurement

- Promotional Events: Use standard synthetic options. Priority is cost control and fast delivery.

- E-commerce Retail: Use high-grade PU or microfiber. Priority is the brand presentation and durability.

- Luxury Brands: Use genuine leather. Priority is brand prestige and long-term product life.

- الاستخدام الصناعي: Use heavy-duty synthetic leather. Priority is strength and consistent quality.

Choosing the right leather is about cost management and risk reduction. By selecting a material that matches your business model, you ensure that your quality is consistent and your margins remain healthy. Always communicate your specific needs to your supplier early to get the best material match and avoid logo printing defects or material waste.

الخاتمة

Leather choice is a strategic cost management tool. Pick artificial leather for high volume and predictable quality. Choose natural leather for premium positioning and higher margins.

Frequenty Asked Questions

Q: How does leather thickness affect the final shipping cost for bulk orders?

A: Heavier leather significantly increases the total weight of the shipment. Choosing a thinner but stronger synthetic material can lower your air or sea freight expenses, which is often an overlooked part of the total landed cost.

Q: Can synthetic leather be recycled if the project focuses on sustainability?

A: Yes, materials like rPET leather (recycled polyester) are available. They provide a strong eco-friendly story for your brand while keeping material costs lower than new natural hides.

Q: Does the color of the leather impact the lead time of a wholesale project?

A: Standard colors like black, beige, or navy are usually in stock. Custom Pantone-matched leather requires extra time for lab dips and dyeing, which can extend your lead time by 10-15 days.

Q: How should I choose leather for bags used in extreme weather conditions?

A: For very cold or humid climates, high-grade PU or silicone leather is often better because it is engineered to resist cracking and mold, whereas natural leather requires expensive treatments to withstand these conditions.

Q: Why does the smell of leather matter in B2B procurement?

A: Low-quality PVC often carries a strong chemical odor that can result in customer returns. High-quality PU or natural leather has a neutral scent, which is crucial for the "unboxing experience" and perceived value.

Q: Is it possible to mix different leather types on a single bag design?

A: Yes, a common cost-saving strategy is to use durable microfiber for high-wear areas (like handles and corners) and standard PU for the main body. This balances durability with budget.

Q: How does the grain pattern on synthetic leather affect the branding logo?

A: Deep grain patterns can cause small logo details to look blurry or broken. If your design has a complex logo, smooth leather is much better for ensuring sharp silk-screen printing or embossing results and avoiding defects.

Q: Does the lining material change based on the exterior leather choice?

A: Usually, yes. To maintain a consistent price-value perception, premium leather exteriors are typically paired with higher-density cotton or polyester linings, while standard PU bags often use lighter lining materials.

Q: How can I verify the quality of a leather batch before full production starts?

A: You should always request a Pre-Production Sample (PPS). This allows you to physically test the material’s hand-feel, color accuracy, and scratch resistance before the factory cuts the bulk fabric.

Q: Will switching to a different leather type require new cutting molds?

A: Generally, no. Most leather types can be cut using the same physical or digital molds. This makes it easy to test different materials (e.g., switching from PU to Canvas) without incurring new tooling fees.