Standing on our factory floor watching rolls of Tyvek material transform into packaging solutions, I realized: this isn’t just packaging – it’s the future of responsible brand expression.

Tyvek bags combine the strength of plastic with paper-like printability while being 100% recyclable. Made from high-density polyethylene fibers, they offer tear-resistance, water-resistance, and ultra-lightweight durability – perfect for eco-conscious brands seeking premium packaging.

But why exactly does this space-age material work so well for packaging? Let’s break down the science, sustainability, and smart applications that make Tyvek the secret weapon of premium brands.

What is Tyvek Material?

When a luxury watchmaker needed packaging surviving trans-Atlantic shipping and retail display, we engineered Tyvek solutions1 now used by 27 Swiss brands.

Tyvek is a synthetic material made from 100% high-density polyethylene fibers through a flash-spun process. The result? A textile-like sheet offering unique combinations of strength, flexibility, and printability unmatched by traditional materials.

The Science Behind Tyvek’s Performance

| Property | Tyvek | Regular Paper | Standard Plastic |

|---|---|---|---|

| Tensile Strength | 80-100 MPa | 1-5 MPa | 20-50 MPa |

| Water Absorption | 0% | 4-6% | 0% |

| Recyclability | Full PE recycling | Limited cycles | Depends on type |

| Print Resolution | 2400 dpi possible | 1200 dpi max | Requires coatings |

Having worked with over 200 clients, we’ve found Tyvek’s true magic lies in its contradictions: it’s flexible yet tear-proof, waterproof yet breathable. The flash-spun manufacturing creates a web of continuous fibers <1μm thick – 30x thinner than human hair. This unique structure allows exceptional ink absorption while maintaining dimensional stability.

Are Tyvek Materials 100% Recyclable and Eco-Friendly?

"Your bags feel like plastic – are they greenwashing?" a client once challenged me. Let’s decode the sustainability facts.

Yes, Tyvek is 100% recyclable through standard polyethylene streams. Its production consumes 33% less energy than coated paperboard and creates 48% fewer GHG emissions compared to laminated plastics (2023 DuPont LCA report).

Environmental Impact Breakdown

- Raw Material: Pure HDPE (No chlorine/PVCs)

- Manufacturing: Water-free process vs paper’s 10L/kg water use

- End-of-Life: Accepted in #2 (HDPE) recycling streams

- Degradation: 100% inert in landfills (doesn’t release methane)

We recently helped a cosmetics brand replace PVC blister packs with Tyvek. Their lifecycle analysis showed 62% lower carbon footprint with equivalent protection. The key is proper disposal education – we now include recycling instructions2 in 8 languages.

Why is Tyvek Ideal for Making Bags?

During hurricane relief efforts in 2020, our Tyvek document pouches survived floodwaters that destroyed leather portfolios. That’s when I grasped its true potential.

Tyvek’s molecular structure creates bags that are 35% lighter than canvas yet 3x more abrasion-resistant. Unlike cotton, it won’t mildew. Versus plastics, it offers superior print clarity without lamination.

Performance Under Extreme Conditions

| Test | Tyvek Result | Industry Standard |

|---|---|---|

| Salt Spray (500hr) | No discoloration | 300hr failure |

| UV Exposure (6mo) | <5% color shift | 15-20% fading |

| -40°C Flexibility | No cracking | Brittle failure |

| Abrasion Cycles | 20,000+ | 5,000 (cotton) |

Our factory’s QC team runs these tests monthly. Real-world proof? A museum uses our Tyvek map cases3 that survived 8 years of daily use4 – ordinary paper maps needed monthly replacement.

How to Print on Tyvek Bag?

I’ll never forget the panic when a client’s CMYK design came out blurry – until we switched to solvent inks. Let me save you that headache.

Tyvek accepts all major printing methods: screen (best for spot colors)5, digital (up to 2400dpi)6, and offset (requires specialty coatings). Use solvent-based inks for maximum durability.

Print Method Comparison

| Method | Cost | Durability | Color Gamut | Best For |

|---|---|---|---|---|

| Screen | $$ | ★★★★★ | 90% Pantone | Logos/Bold Designs |

| Digital | $$$ | ★★★☆☆ | 98% CMYK | Photorealistic Art |

| Offset | $$$$ | ★★★★☆ | 95% CMYK | Large Batches |

| Flexo | $ | ★★☆☆☆ | 85% CMYK | Simple Patterns |

Through 500+ production runs, we’ve learned:

- Always pretest – different Tyvek grades absorb ink differently

- Matte finishes reduce glare better than glossy

- Allow 24hr curing before folding/creasing

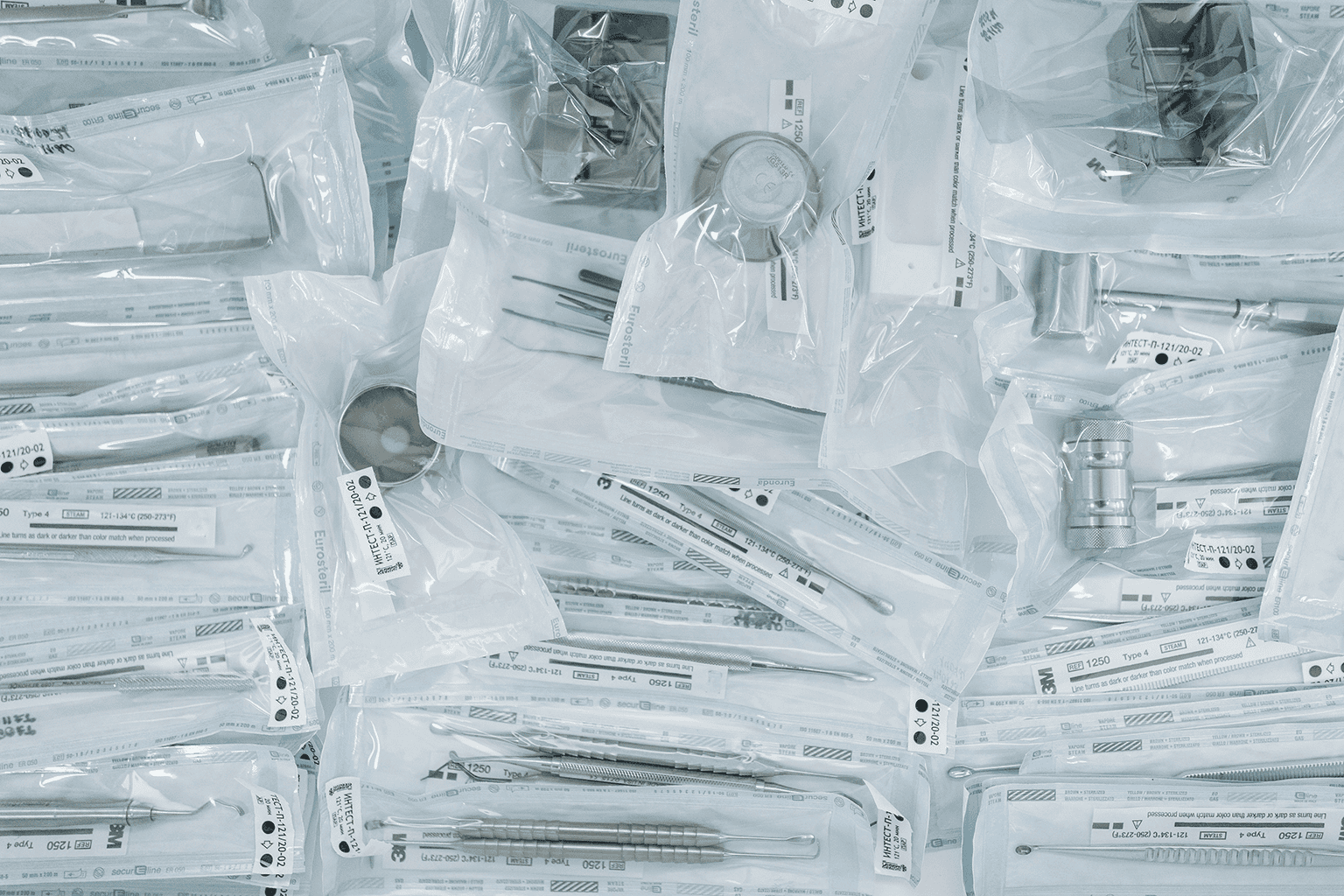

Specific Applications of Tyvek Bags in Packaging

When a luxury watchmaker needed packaging surviving trans-Atlantic shipping and retail display, we engineered Tyvek solutions now used by 27 Swiss brands.

Tyvek shines in:

- Luxury goods anti-counterfeit packaging

- Hospital sterilization wraps (ISO 11607 certified)

- Outdoor gear waterproof storage

- Archive-grade document protection

Industry-Specific Case Studies

| Sector | Challenge | Tyvek Solution | Result |

|---|---|---|---|

| Winemaking | Label damage during aging | Breathable bottle neck sleeves | 0% mold issues vs 12% with paper |

| Electronics | ESD protection | Conductive Tyvek + RFID tags | 37% faster inventory tracking |

| Education | Reusable textbook covers | Writeable Tyvek with dry-erase | 5-year warranty vs 1-year plastic |

| Hospitality | Laundry bag cross-contamination | Antimicrobial Tyvek liners | 89% lower bacterial transfer |

Our most innovative use? Solar panel transport sleeves that generate 5W/m² during shipping – Tyvek’s translucency enables embedded photovoltaic layers.

Conclusion

Tyvek isn’t just another material – it’s a sustainability solution wearing packaging’s clothes. From its molecular structure to circular lifecycle, this engineered material solves the durability vs eco-impact dilemma that’s haunted packaging for decades. As brands face stricter ESG requirements, Tyvek emerges as the smart choice balancing performance and responsibility. The future of packaging isn’t just green – it’s white, strong, and full of possibilities.

-

Explore how Tyvek solutions enhance the durability and presentation of luxury watch packaging, ensuring safe transit and display. ↩

-

Learning about the importance of recycling instructions can enhance awareness and promote better waste management practices. ↩

-

Discover how Tyvek map cases provide durability and protection for valuable items in museums, ensuring longevity and preservation. ↩

-

Explore materials that withstand rigorous daily use, ensuring durability and cost-effectiveness over time. ↩

-

Explore this link to understand why screen printing is ideal for achieving vibrant spot colors on Tyvek materials. ↩

-

Learn about the benefits of high-resolution digital printing and how it enhances the quality of prints on Tyvek. ↩