The market for canvas tote bags is estimated to grow at a rate of 4.60% in the next seven years. More and more businesses are adopting custom tote bags to build their empire. Are you also exploring customized tote bags? The most important thing to consider is the printing method.

Common methods include: screen printing, heat transfer, DTG, sublimation, flocking, and more! The diverse range of printing methods available provides limitless opportunities. Whether you like vibrant graphics or realistic photographs – anything is within reach. The type of method you choose depends on your canvas bag requirements.

Want to learn more about how to choose the right printing method? Read on to dive deep into the exciting world of custom canvas bag printing!

Top 7 Printing Methods For Custom Tote Bags

Screen Printing

How It Works?

Screen printing or silk printing, uses printing screens made out of nylon mesh and a steel frame. These screens are like a template through which paint is pressed for application. The colors are applied one by one on separate screens. The patterns are then transferred onto the fabric in layers.

Screen printing is one of the most uncomplicated methods of printing. But this also means its applications are limited. It allows you to use up to 6 colors for your designs in theory,but in real production, This method is not recommended for multi-color prints, we only use screen printing or silk printing with less than 3 colors.

There are multiple types of screen printing available, including:

- Rotary Screen printing – For ready-made tote bags.

- Flat-screen printing – to print on rolls of fabric.

- Hand-screen Printing – Hand-made prints.

When To Use It?

Since this method is fairly primitive, it is most effective for simple prints such as logos or letters. Screen printing cannot achieve a seamless color transition. This means it’s almost impossible to print good photographic images with it. Screen printing works well with simple geometric patterns and shapes.

Screen printing is also effective for bulk printing of simple patterns. An ideal example is if you want to print a small polka dots pattern on fabric.

Pros

- Highly cost-effective for bulk printing.

- Durable and long-lasting prints

- You can also do it at home.

- Good for block-printing style.

Cons

- Preparing screens may be cost-intensive.

- Not suitable for individual prints or prints in a very small volume.

- Can only best print for 1 or 2 colors

- Not so accurate in chromatography

Heat Transfer

How It Works?

Heat transfer printing uses pressure and heat to apply designs to tote bags. Heat-applied materials with an adhesive side are used for this method. The adhesive is activated when heat is applied through an iron. This makes the material stick to your canvas bag. It can also be done through heat transfer paper and printer. There are two main types of heat transfer techniques:

- Vinyl Heat Transfer

- Digital Print Heat Transfer

When To Use It?

Heat transfer printing can only be used for materials that can handle the heat. Most reusable tote bag materials are not averse to heat. This makes heat transfer a viable option. You cannot use heat transfer for synthetic materials. This method is good for transferring highly realistic photo images to bags.

Pros

- Small volumes can be made quickly.

- Great for photographic, full-color prints.

- There are no limits to which colors can be used.

- Good for both dark and light-colored fabrics.

- Nice and vivid prints on canvas, jute, non-woven fabric bags

Cons

- High filming costs, costs calculated by the printing area. suitable for large quantity and colorful patterns.

- Making bulk orders can be time-intensive.

- Heat transfer prints make the fabric stiff.

- Prints cannot be ironed.

Sublimation

How It Works?

Sublimation printing is much like heat transfer printing with some differences. The method transfers designs printed on sublimation paper. Similarly, to heat transfer, it uses heat and pressure to turn solid ink into a gaseous state. When the ink cools down it turns into a solid again and adheres to the fabric. This makes the print a part of the fabric without adding an extra layer.

What’s The Difference Between Heat Transfer And Sublimation?

If heat transfer and sublimation are almost similar, then what are the differences? When should you use sublimation? The answer to that is quite simple. The process of sublimation makes the ink a part of the fabric. On the other hand, heat transfer just adds a layer to it. This makes sublimation prints more durable and gives a natural feel.

However, sublimation can only be used with a limited number of fabrics. Sublimation mainly works on polyester fabrics only. Bags that are made with 100% cotton cannot hold the sublimation ink. Blends of polyester and cotton can also be used. But they result in faded, non-vibrant prints. Another limitation is that the fabric needs to be white or light-colored.

Pros

- Low startup cost, can be set up at home.

- Gives a very silky and natural feel.

- Highly durable and long-lasting.

- Best for printing on polyester or polyester blended canvas.

Cons

- Cannot be used for printing on 100% cotton.

- Faded results on polyester blends.

- Not recommended for dark-colored fabrics.

Gravure Printing

How It Works?

Gravure printing, also known as rotogravure printing, creates laminated canvas bags. The process has two parts. In the first step, the design is printed on a film. The second step involves the lamination of this film onto the fabric. It creates a seamless print and mainly uses machines for the entire process.

The process is known for creating highly durable and waterproof prints. The film comes in two forms, matte and bright form with more variation.

When To Use It?

Gravure printing is ideal for bulk production and high-volume projects. For such projects, it minimizes the time and costs. However, the equipment and starting cost is fairly high. This means it’s not recommended for small volumes. It is mostly used for canvas bags in which large areas are to be covered with color.

Pros

- The printing quality is excellent.

- Produces highly durable prints.

- Ideal for large volume projects.

Cons

- High entry cost.

- Equipment and preparation are expensive.

- Not ideal for small volumes.

- Long preparation time.

DTG Printing

How It Works?

DTG or direct to garment printing uses digital technology to create high-quality prints. It utilizes the same technology as an inkjet printer. The nozzles of the printer spray ink onto the garment. This ink then dissolves and integrates into the fabric.

The results are highly realistic and sharp prints for your bags. Unlike other methods, the production cycle of DTG is really short. Since there’s little to no preparation needed, you can get right into creating.

When To Use It?

There are unlimited color options when working with DTG printing. It is very suitable for printing pictures and realistic images. However, DTG printing is not good with transparency. The design needs to be completely opaque to translate well. DTG printing also creates less waste and is more eco-friendly.

If you’re looking for a sustainable method that produces high quality with low entry costs – DTG is the way to go.

Pros

- Easy to print small volumes or one-offs due to low setup time. Best for sample printing

- Creates high-quality, photo-realistic prints.

- No color limitations.

- Can be used for a sustainable, low-waste business model.

Cons

- Does not work well with transparencies.

Machine Embroidery

How It Works?

Apart from printing methods, many tote bags are also embroidered. While hand embroidery is an option, machine embroidery is easier. This method required an embroidery digitizer. It is much like a printer that embroiders designs for you. You simply have to feed a design into it and let it do the job!

When To Use It?

If you want your tote bags to have custom embroidered designs then this is a great option. This can give a hand-embroidered look in a short time. The process is also fully automated and non-labor intensive.

Pros

- Short turnaround time.

- Less likelihood of human error.

- Easier to use for large volumes as the machine is faster than humans.

- Gives a bespoke and high-quality end result.

Cons

- You need an embroidery digitizer machine for this.

Flocking

How It Works?

Flock printing uses cotton or synthetic fibers to create an embossed effect. These fibers are transferred onto an adhesive to which they stick and create a raised layer. The short fibers leave a velvety surface on the print. The fibers can easily be dyed to give color to the prints.

When To Use It?

Flocking is widely used for the printing of team t-shirts and other paraphernalia. When it comes to tote bags, flocking can add a really cool effect. Flocking is perfect for an embossed, velvety finish.

Pros

- Gives a soft and velvety finish.

- Looks highly professional and of high quality.

- Creates a textured, embossed style.

Cons

- Only good for creating simple embossed designs.

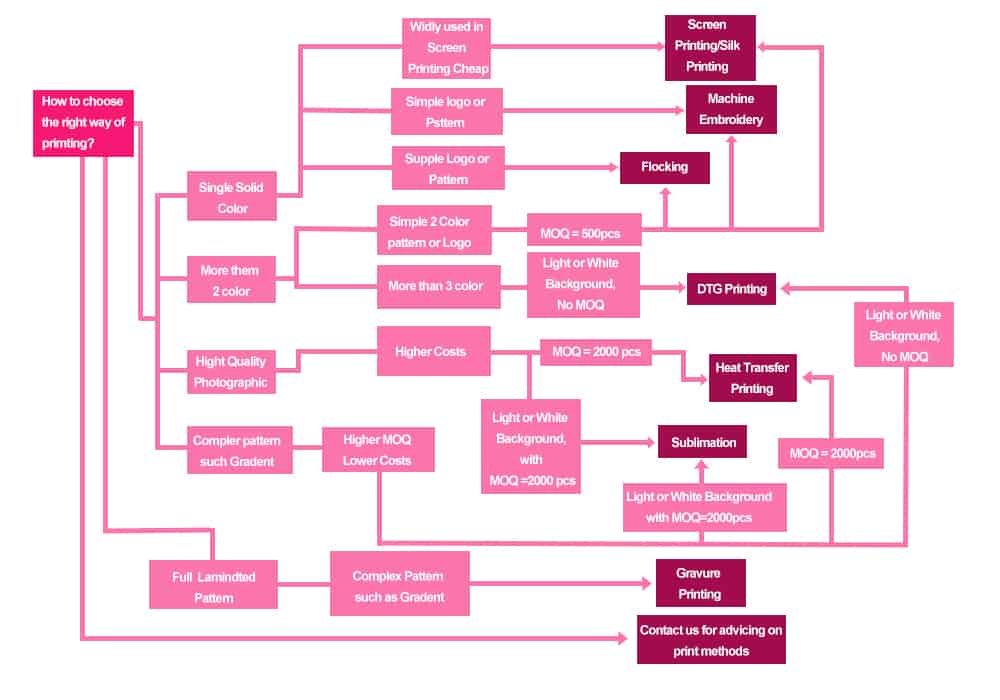

How To Choose The Appropriate Way Of Printing

Now you know all about the seven most common printing methods. The question remains, which one should you go for? The answer depends entirely on what kind of end-product you’re looking for.

Here’s a table that highlights what kind of printing method will suit you best:

| Type of Printing | Colors | Type of Finish | Startup Cost | Turnaround Time | Large vs. Small Volume |

| Screen Printing | Most suitable for 1 or 2 colors . Best for block prints. | Glitter, foil, puff ink, neon, etc. | Low startup cost. | Labor intensive if not automated. Takes more time than others as colors are applied one at a time. | Large volumes. |

| Heat Transfer | No color limitation. Photorealistic prints. | Makes fabric tough. | Low startup cost for home printing, Only need a heat transfer printer .But high filming costs in mass production | Little to no setup time.May take more time for bulk orders. | Small volumes for home printing and big volume in mass production. |

| Sublimation | No color limitation.Photorealistic prints. | Natural, soft finish.Not for dark fabrics. | Comparatively low startup cost, can do at home. | Little to no setup time.May take more time for bulk orders. | Small volumes at home or or big volumes in ass production |

| Gravure | No color limitation. | Good for Large area color coverage.Matte and shiny prints. | High start-up cost. | Long preparation time. | Large volume in Mass production.. |

| DTG | No color limitation. Good with RGB colors.Photorealistic prints. | Matte and shiny prints. | Low startup costs. | Little to no setup time. | Both. Good for small volumes and one-offs too. |

| Embroidery Machine | Embroidered, limited options. | Embroidered finish. | Need an embroidery digitizer so it might be cost-intensive. | Faster than hand embroidery. | Both. |

| Flocking | Fibers are dyed to give color. | Embossed, velvety finish. | Might be costly. | More time-intensive than normal prints. | Both. |

Final Thoughts

Canvas tote bags can help you boost your marketing strategy for major success. The first thing to consider is the printing method. The printing technique determines the investment and turnaround time of your orders. It also affects how your bags end up looking. Hence, choosing the right method is highly important!

New to custom tote bag manufacturing? Our in-depth guide to printing methods can help you get started.

2 Responses

Hi

I am going to start a small business of online selling of canvas tote bags. I am manufacturing 100% cotton canvas bags and am really confused regarding the printing technique to choose. Not getting the desired result in screen printing if going for 3-4 colors on black canvas bag. Print quality on basic canvas color is satisfactory but not extraordinary. Kindly suggest the best printing technique for 100%COTTON canvas bags.

Hello,Ms Anand,

Normaly screen printing only work on 1 or 2 colors on both white canvas or black canvas,3 color or 4 colors sometimes also ok,but as you see,it’s not easy to do chromatography.

For 100% cotton canvas bag,with colors more than 4,it’s better use digital printing. but that also doesn’t work nice on black cotton canvas.

As you run a small business,what I suggest is as below:

1.Buy a small digital printing machine,it can both print 1,2 or more colors. which is more easier to print. but not suitable for black canvas bag.

2.If you really want to print on black canvas ,2 solutions:

a.print only 1 or 2 color with screen printing both on white and black canvas

b.Buy a small heat transfer machine to print color more than 3 ,and you also need to buy the heat transfer paper

Hope my answer is helpful to you.